आपने अपने बिल्कुल नए पैडल मिक्सर के लिए पर्याप्त पैसे चुकाए

इसके रख-रखाव के लिए समान भुगतान न करें

निम्नलिखित युक्तियों से अपना पैसा और अपना समय बचाएं:

#1. समसामयिक और हल्के मिश्रण के कार्य-जिसमें मुख्य रूप से पेंट या वार्निश शामिल हैं-पारंपरिक ड्रिल द्वारा भी किए जा सकते हैं(2 स्पीड वन अच्छा करेगा) पैडल अटैचमेंट के लिए एडाप्टर से सुसज्जित

#2 मोर्टार जैसे चिपचिपे और चिपचिपे पदार्थों को मिलाना,प्लास्टर,टाइल चिपकने वाले ,फिलर्स,वगैरह. गियर मैकेनिज्म से सुसज्जित कम से कम 1300W के शक्तिशाली मिक्सर की आवश्यकता है.

#3 चिपचिपी सामग्री को हिलाने के लिए रोटरी हथौड़ों और कॉम्पैक्ट ड्रिल का उपयोग करने से बचें/. या तो मोटर जल सकती है या सेफ्टी क्लच ख़राब होने की संभावना है.

#4 यदि आप ऐसे पेंट या सामग्री मिला रहे हैं जो पूरी बाल्टी पर बिखर जाते हैं ,सॉफ्ट स्टार्ट सुविधा वाला मिक्सर खरीदना एक बुद्धिमानी है.

#5 बाल्टी को मिक्सिंग ब्लेड के आकार के अनुरूप भरें, ताकि ब्लेड पूरी तरह से सामग्री में डूब सके

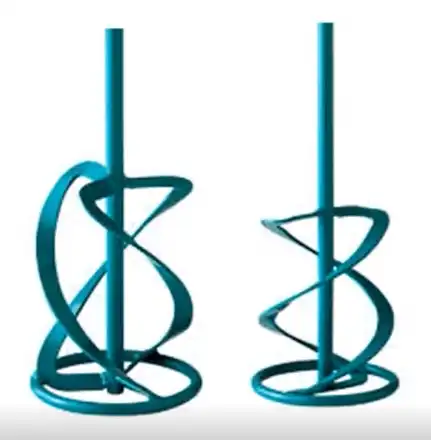

#6 चप्पू का व्यास बाल्टी के आकार का लगभग एक तिहाई होने दें. रास्ते में, पैडल कंटेनर में बिना फंसे या बाल्टी को नुकसान पहुंचाए आराम से फिट हो जाता है

#7 सावधान रहें कि मिक्सर द्वारा स्वीकृत पैडल अधिकतम व्यास-120 मिमी से अधिक न हो,140मिमी,160मिमी सबसे अधिक उपयोग किए जाने वाले आकार हैं. अन्यथा, धुरी क्षतिग्रस्त हो सकती है

#8 कम चिपचिपाहट के लिए(पेस्टी जैसा पतला-तरल) पेंट जैसी सामग्री,वार्निश,गोंद,आदि-एफएन और एलएक्स प्रकार के पैडल अधिकतर लागू होते हैं.

#9 मध्यम चिपचिपाहट के लिए(चिपचिपा से सख्त) चिपकने वाली सामग्री जैसी सामग्री,सीलंट,फिलर्स,वगैरह. –DLX और KR प्रकार के पैडल अधिकतर उपयोग किये जाते हैं.

#10 भारी चिपचिपाहट के लिए(कठिन से भारी) मोर्टार जैसी सामग्री,ठोस,प्लास्टर,एपॉक्सी रेजि़न,वगैरह. –एमकेएन और डब्ल्यूके प्रकार के पैडल व्यापक रूप से उपयोग किए जाते हैं.

अतिरिक्त युक्तियाँ: कम सेवा लागत पर लंबे उपकरण जीवन को सुनिश्चित करने के लिए विश्वसनीय आपूर्तिकर्ताओं से मिक्सिंग पैडल का उपयोग करें